We process a lot of labels on rolls, both spot color and four-color (CMYK). People often ask about the roll label terms we use on our quotes and landing pages. So here’s a short primer of terms you might see when ordering labels on rolls.

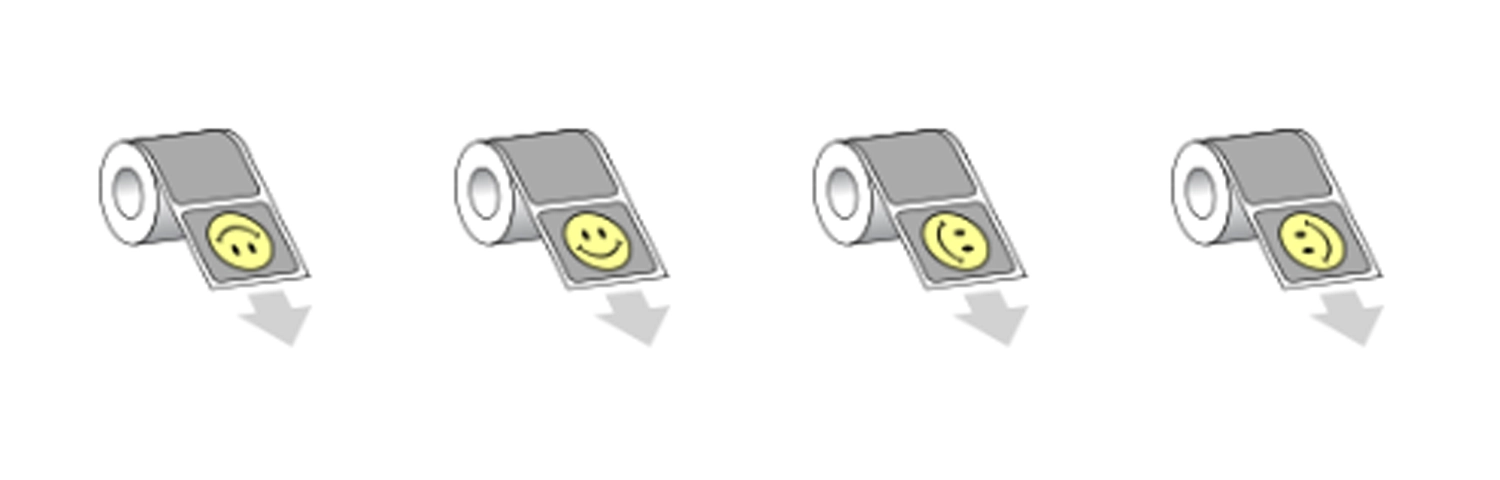

Unwind Direction

The first, slightly confusing, roll label term is unwind direction. This refers to the orientation of the labels on the roll. There are four ways to unwind roll labels, used in two styles, for a total of eight options for making them.

Which part of the label comes off the roll first determines the four directions. The directions include top off, bottom off, right off, and left off.

The top off direction means the label faces away from the roll’s end. The bottom off direction means the label faces the roll end. The position of the label on the roll also determines the right off and left off directions.

Roll Winding

Additionally, two ways exist for winding the labels on the roll. The most common way is “wound out,” where the label face is on the outside the roll. You can also wind in rolls, with the labels on the interior of the roll and the backing on the outside.

Our roll label pages only offer the “wound out” style for the most commonly requested quoters. These quoters are multi-purpose (spot color) and process (CMYK or 4-color). We can also do “wound in.” If you desire that style, you can directly contact Customer Care from the page to order that.

If you’re using a machine to apply your labels, check its specs for the unwind preference. If you are manually putting on the labels, the direction of the roll doesn’t matter much. However, one direction might be easier for you.

This depends on your situation. Consider your work space and labeling setup before you decide. You can choose the default option or we can decide the unwind direction for you.

Roll Dimensions

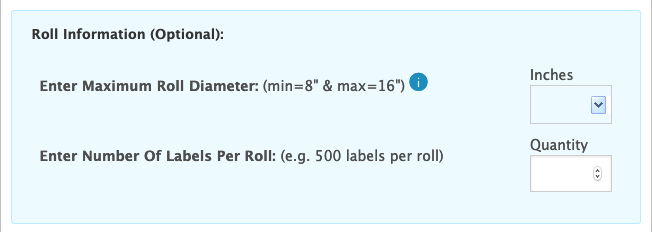

We have two choices for the quoters: one for machines (maximum roll size) and one for hand use (labels per roll).

For machine labels, get the biggest roll your machine can handle to reduce how often you have to reload. So you’d enter the maximum diameter, according to your machine specs, in the first field. We can make rolls that are between 8” and 16” inches in diameter.

If you are manually putting on labels, it may be more efficient to use smaller rolls. This way, multiple people can label your products simultaneously. Use the second optional field here to enter the number of labels you want per roll. This is most commonly between 500 to 2,500 labels per roll, but can be as little as 250 per roll.

So, for example, if you’re ordering 1,000 labels, and enter 250 per roll in this section, you’ll get four rolls. Assuming you have the people available for label application, you can apply them four times as fast!

Core Size

Our standard core size is 3” in diameter. Most people prefer the 3” size, so it is the default on the quoter. We do also offer 1” and 0.75” cores. The smaller sizes are more geared to specialty uses.

Perforation / Pieces

Most roll labels are designed for users to peel off the roll and apply immediately. If you have a different idea in mind, say giving out labels to customers for their use, we do offer a couple of options.

In our roll label program, you can request perforations between each label on the roll. This makes it easier to remove and distribute one or two labels at a time.

In our process color roll program, you can also request pieces for many of the shapes and sizes. (These do not ship as a roll; they will come as individual labels.)

Because of the extra work involved, there is an additional charge for both perforations and pieces.

Tips on Storage

Don’t store rolls on their sides if you’re not using them. It can damage the core or labels and make them fall off the shelf easily. If you have more than one roll, you can just stack them up. If it’s humid, you may want to protect them with a plastic bag.

Don’t store them in direct sunlight, near a heat source, or in a warehouse without air conditioning. Heat and extreme cold are not good for the adhesive. If you do not store your rolls properly, your labels may not remain as sticky a year or two from ordering.

You can also hang your rolls on pegs, especially if you go through rolls fairly quickly. We use both wall-mounted and free-standing metal peg racks to store our rolls of material on the Production floor, for instance. Make sure any pegboard or hooks used are in a clean, dry area with a minimum of disturbance.

Conclusion

Understanding label terminology is the key to making informed decisions when it comes to your labeling needs. At Maverick Label, we simplify label terms so you can choose labels that go beyond your expectations. Trust Maverick Label for labels that speak your language and elevate your messaging.