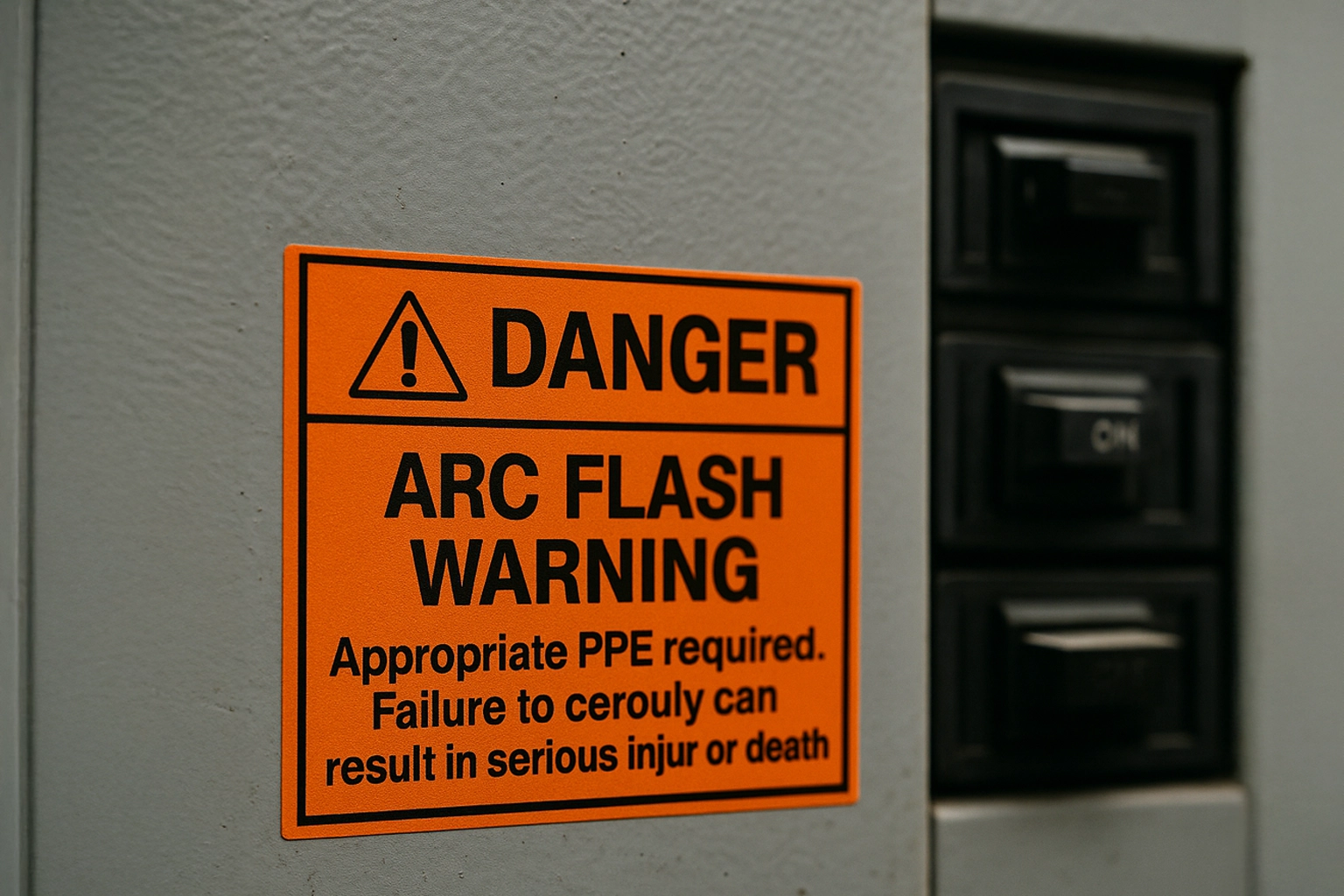

Arc flashes don’t announce themselves. But your labels can. If you’re managing facility safety, one of the smartest things you can do is put warning labels right where arc flash risk lives, on panels, breaker boxes, and anywhere current could jump. You’ll make danger visible before someone reaches for a handle.

The Unseen Risk That Needs a Label

Arc flashes can happen without warning, just one slip, one loose wire, one tool in the wrong spot. That’s all it takes for a superheated plasma blast to erupt. And it doesn’t just singe. It can blind. Burn. Kill.

Arc detection systems are your eyes and ears. Labels? They’re your voice. Clear warnings placed on the right gear make sure everyone knows where the risk is, and what to do about it.

Use labels to:

- Mark arc-prone panels before someone opens them

- Flag gear with arc detection systems installed

- Remind teams that PPE isn’t optional

- Keep maintenance logs traceable with QR codes or serial numbers

If you’re relying on memory or spreadsheets alone, you’re leaving a gap.

Where to Label for Arc Detection Safety

You already know your high-risk zones. Let’s make them impossible to ignore.

High-impact label locations:

- Main electrical panels

- Breaker boxes and MCCs

- Bus ducts and load centers

- PPE cabinets or arc flash kits

- Panels monitored by arc detection sensors

Label placement matters. Put warnings where hands reach and eyes go first.

Build Labels That Hold Up in Harsh Environments

A good label doesn’t fade. It doesn’t peel off after a hot summer or a humid shutdown. If it’s warning people about arc flash risk, it better last.

Use:

- Industrial-grade vinyl or polyester (handles heat, oil, abrasion)

- Adhesives made for powder-coated or painted metal

- Fade-resistant inks (especially if outdoors or exposed to UV)

- Writable surfaces or printed serial numbers for inspections

- QR codes that point to inspection logs, safety sheets, or panel diagrams

What the Experts Recommend, and Why It Matters

Arc flash labeling isn’t just a best practice. It’s part of how you meet key safety standards like NFPA 70E, which outlines electrical safety in the workplace. The standard specifically calls for equipment to be marked with arc flash warnings where a hazard exists.

Why that matters: It’s not just about compliance. Labels give your team the visual reminders they need when stress is high and response time is short. When done right, labeling can cut down on hesitation, improve PPE usage, and even reduce insurance risk.

For more context on labeling and arc flash safety, read the NFPA 70E Standard Overview directly from the source.

A Smarter Labeling Plan for Arc Detection Zones

Here’s how to put labels to work for real safety gains:

- Walk the floor: Identify gear with arc sensors, high fault potential, or tight clearance.

- Label access points: Panels, doors, breaker handles—anywhere someone might interact.

- Add tracking: Use QR codes or serial numbers so inspections stay documented.

- Tag test intervals: Writable labels or colored inspection tags can show the last service date.

- Make it part of training: Everyone from new hires to contractors should know what those labels mean.

When everyone understands the label system, nobody has to second-guess the hazard.

Use Fall Prep to Fix Label Gaps

Fall’s coming. Cooler temps. New energy loads. Shutdowns. Maintenance. It’s prime time for safety checks, and for fixing any label blind spots.

Add or replace labels when:

- New arc detection systems are installed

- Panels are reconfigured or moved

- Labels are missing, faded, or peeling

- You’re prepping for OSHA or NFPA audits

Every panel you label now is one less unknown later.

Make Labeling Part of Smarter Asset Management

Labeling arc detection zones isn’t just about safety, it’s also a key part of knowing what equipment you have, where it’s located, and what condition it’s in.

When you add QR codes or serial numbers to your labels, you’re creating a simple but powerful asset tracking system that ties directly into inspections, service history, and compliance.

Want to see how it fits into a broader strategy? Check out our post on what asset management means and why it matters. It shows how labeling supports better control, fewer surprises, and safer operations.

Quick Recap: What to Do Now

If you’re managing arc detection or prepping for fall facility safety, here’s what to focus on:

- Label all arc-prone panels and equipment clearly

- Choose durable materials that can handle heat, dust, and time

- Add QR codes or serial numbers for inspection tracking

- Use this season’s maintenance window to fill in label gaps

- Make labeling part of your long-term asset management strategy

Simple steps, major impact. One label can stop the wrong reach, or help the right response.

Need Labels That Don’t Quit?

If you’re in charge of safety, your labels can’t afford to fall short. They need to stick, stay legible, and work just as hard as the gear they’re protecting. That’s where high-performance arc flash warning labels come in, built to handle heat, abrasion, and tough plant conditions without flinching.

Labeling for Arc Detection FAQ

Arc detection systems sense electrical arc faults by monitoring for light, heat, or overcurrent spikes. They help reduce the chance of injury by cutting power before a flash happens.

Because labels make hidden risks visible. When you mark arc-prone panels or gear, you reduce the chance of someone getting too close without protection.

Anywhere arc detection systems are active or arc flash risk exists—like breaker boxes, MCCs, bus ducts, or high-voltage cabinets.

Yes. QR codes can link to inspection logs, panel schematics, or even safety procedures. Great for audits and large facilities.

Look for polyester or vinyl with permanent adhesive. You want something that won’t peel under heat or dust. UV-resistant inks help labels last longer outdoors.

At least annually, or whenever panels are serviced. Inspection labels help keep logs visible and easy to check.

Not always by code, but they’re a smart way to support compliance, track testing, and avoid miscommunication during audits.