Keeping track of physical assets is essential for any business. A fixed asset tagging system helps label, identify, and monitor equipment efficiently. Whether you’re managing IT devices, machinery, or office furniture, implementing a structured process ensures everything is accounted for and easy to locate.

Here’s how to build an effective tracking system that improves inventory management, prevents asset loss, and streamlines operations.

Step 1: Assign Unique IDs to Each Asset

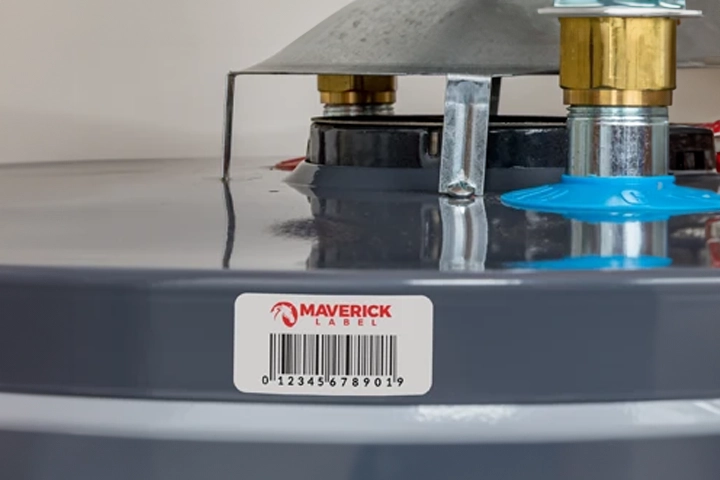

Every item needs a unique identifier to distinguish it from similar assets. These IDs are typically printed on labels in the form of barcode labels, QR asset tags, or RFID asset tags. Assigning a unique ID ensures seamless tracking and quick scanning within an asset management system.

Using a fixed asset tagging method ensures that high-value assets are always properly identified and tracked.

Step 2: Choose the Right Labels

Selecting the right labels depends on the type of physical assets you need to track. Consider these options:

- Barcode labels – A cost-effective choice for offices and IT equipment.

- QR asset tags – Store detailed information and allow mobile scanning.

- RFID asset tags – Enable remote tracking without direct scanning.

- Metal asset tags – Ideal for harsh conditions, offering extra durability.

The right labels improve tracking efficiency and ensure long-term readability.

Step 3: Label Assets Correctly

For effective tracking, place labels where they are easy to scan but not easily damaged or removed. Here are some best practices:

- Asset tags for laptops – Position labels on the bottom or back.

- Machinery and tools – Use metal asset tags in low-wear areas.

- Office furniture – Apply labels on the inside or underside of panels.

Proper placement improves scanning accuracy and extends the life of each label.

Step 4: Use an Asset Management System

A fixed asset tagging system works best when paired with an asset management system. This software allows businesses to:

- Track asset locations and usage in real time.

- Log maintenance schedules and historical data.

- Generate reports for audits and compliance tracking.

A digital system reduces manual errors and improves overall efficiency.

Step 5: Implement a Color-Coding System

Using tag colors simplifies identification and organization. Common color codes include:

- Red – High-priority or restricted-use equipment.

- Blue – IT and office assets.

- Yellow – Frequently used tools and machinery.

This method speeds up audits and minimizes confusion during asset identification.

Step 6: Keep Records Updated

Tagging assets is only the first step—keeping records current is just as important. Regular updates should include:

- Scanning assets periodically to confirm location.

- Updating information when items are reassigned or retired.

- Conducting audits to ensure records align with actual inventory.

A well-maintained asset tracking system prevents discrepancies and improves accuracy.

Step 7: Train Employees on Proper Tracking Procedures

An effective asset tagging process depends on proper usage. Employees should be trained on:

- Scanning barcode labels or QR codes correctly.

- Updating entries in the asset tracking system.

- Proper label placement for different types of equipment.

Training ensures consistency and reduces errors in managing your assets.

Step 8: Use RFID for High-Value Equipment

For large inventories or high-value assets, RFID asset tags provide an extra layer of tracking. These labels allow:

- Wireless scanning without direct contact.

- Automated inventory updates.

- Quick asset location for frequently moved items.

Businesses with expensive or mobile assets benefit from RFID-based tracking for added security.

Step 9: Select Labels Designed for Long-Term Use

Durability is key when choosing labels for long-term tracking. Consider these factors:

- Metal asset tags – Best for harsh environments and industrial use.

- Laminated barcode labels – Prevent fading and wear.

- Custom designs – Tailor labels to fit your specific tracking needs.

Using custom asset labels built for durability helps maintain clear identification over time.

Step 10: Conduct Routine Audits

Regular audits ensure that assets are accurately recorded and properly managed. Best practices include:

- Verifying asset locations and conditions.

- Identifying lost or misplaced items.

- Adjusting records in the asset tracking system as needed.

Routine inspections help businesses stay organized and prevent losses.

A Smarter Way to Manage Your Assets

A structured fixed asset tagging system makes it easier to track equipment, prevent loss, and improve efficiency. By selecting the right labels, assigning unique IDs, and integrating an asset management system, businesses can gain full control over their asset inventory.

Check out our durable, high-quality custom asset tags, designed for all types of business needs.

Also, check out our article on how asset marking systems improve tracking and security.

Fixed Asset Tagging FAQs

An asset tag for a laptop is a label with a unique identifier, such as a barcode, QR code, or RFID chip, that helps track and manage the device. These tags are usually placed on the bottom or back of the laptop and linked to an asset management system for easy identification, security, and inventory control.

Assets that are high-value, frequently used, or critical to operations should be tagged. This includes IT equipment (laptops, servers, printers), office furniture, machinery, tools, vehicles, and inventory. Any asset that needs tracking for security, maintenance, or financial reporting benefits from asset tagging.

An example of an asset tag is a durable label with a barcode and a unique identification number. For instance, a manufacturing company may use a metal barcode label on machinery to track maintenance history, or an office may use QR asset tags on laptops for quick check-in/check-out during employee assignments.

Tagging fixed assets is the process of labeling long-term, non-movable assets like office furniture, industrial machines, and equipment with unique identifiers. These tags connect to an asset tracking system, allowing businesses to monitor location, condition, and depreciation for financial and operational management.

Not tagging fixed assets can lead to misplaced or lost equipment, inaccurate inventory records, compliance issues, and financial discrepancies. Without a structured tagging system, businesses may struggle with asset theft, mismanagement, and inefficiencies in maintenance tracking and audits.