Hazard communication labels are more than stickers, they’re OSHA’s second most-cited standard, with over 2,500 violations in 2023. These hazard communication labels function as daily safety tools no EHS manager can ignore, critical for preventing injuries and keeping compliance airtight.

Quick Overview

- OSHA ranks hazard communication among the top safety violations each year.

- Placement, durability, and readability decide whether labels work in real conditions.

- Barcode integration simplifies tracking replacement cycles and expiration.

- The right material prevents fading, peeling, or loss of critical data.

Why Hazard Communication Labels Matter on the Floor

Hazard communication labels make workplaces safer by giving employees instant access to the information they need to handle chemicals, equipment, or processes correctly. According to NIOSH, nearly 13 million U.S. workers are exposed to hazardous chemicals daily.

These labels are the first line of defense, bridging compliance with OSHA’s Hazard Communication Standard (29 CFR 1910.1200) and practical, real-world safety.

The CDC reports that over 400 fatalities annually are tied to acute chemical exposures. Clear hazard communication can mean the difference between a controlled incident and a fatal one. When labels are missing, faded, or inaccurate, the risk climbs quickly.

Material Selection: Durability Is Safety

Labels that peel or fade don’t just look sloppy, they fail at safety. The material has to match the environment:

- Polyester: Resists chemicals, solvents, and abrasion. Ideal for industrial and lab settings.

- Polypropylene (BOPP): Moisture-resistant and flexible, works well for containers and drums.

- Metalized polyester: Handles high heat or exposure near equipment surfaces.

If a label degrades, so does its protective role. That’s why choosing the right material upfront is just as important as accurate wording.

Placement Drives Effectiveness

Where you put a hazard label decides whether it’s noticed or ignored:

- Eye-level placement ensures warnings are seen in seconds.

- Proximity to operating panels helps employees make safe choices before energizing equipment.

- Secondary containers prevent transfer containers from becoming compliance blind spots.

One overlooked pitfall: placing labels near seams or ridges where wear, heat, or moisture can cause premature failure.

Barcode Integration for Smarter Safety

Modern hazard communication labels often include barcodes or QR codes. These extend the label’s usefulness:

- Track expiration dates for chemicals or reagents.

- Link to SDS sheets so employees can scan for instant safety instructions.

- Manage replacement cycles with inventory systems that flag when labels need updating.

This integration closes the loop between compliance and operational efficiency.

Common Pitfalls to Avoid

- Using paper labels in high-moisture or chemical areas, they’ll fail quickly.

- Oversized labels that obscure essential branding or operating instructions.

- Neglecting training—a label only works if employees know how to read and respond to it.

Putting Hazard Labels to Work

Hazard communication labels aren’t optional paperwork. They’re daily-use safety tools that reduce risks, prevent OSHA citations, and protect workers from the very real dangers of chemical and equipment exposure. Investing in durable materials, smart placement, and barcode integration pays off in compliance and safety outcomes.

For a closer look at applications, check out examples of industrial safety labels designed to perform under demanding conditions.

Hazard Communication Labels FAQs

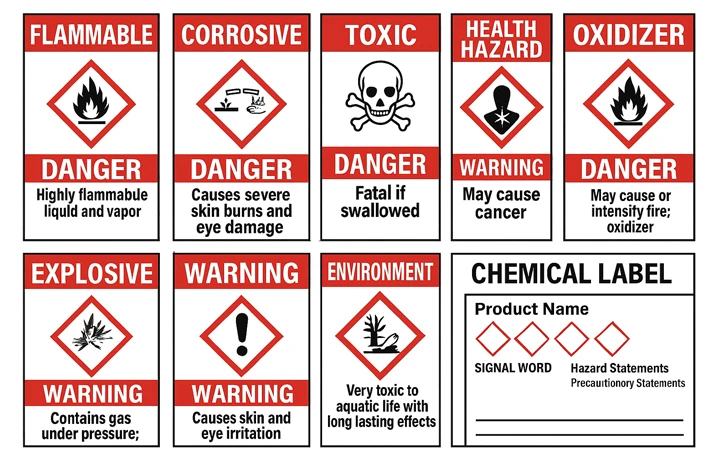

They must include product identifiers, signal words, hazard statements, precautionary statements, pictograms, and supplier information, all aligned with OSHA’s Hazard Communication Standard.

That depends on the material and environment. Polyester or BOPP labels can last years in tough conditions, while paper may only last weeks in high-moisture or chemical settings.

Yes. Adding barcodes or QR codes helps track chemical expiration dates, link to SDS sheets, and integrate with inventory systems.

Incomplete or missing labeling is one of the top issues. OSHA recorded more than 2,500 HazCom violations in 2023, making it the second most-cited standard.

Labels should be placed at eye level or near operating panels where workers interact. Secondary containers must also be labeled to remain compliant.

Yes. All labels must align with the Globally Harmonized System (GHS) of Classification and Labeling of Chemicals to meet OSHA standards.