The purpose of a HazCom (Hazard Communication) program is to ensure that employees are fully informed about the hazardous chemicals they may encounter in the workplace. It outlines what substances are present, how to use them safely, and the steps to take in case of an emergency.

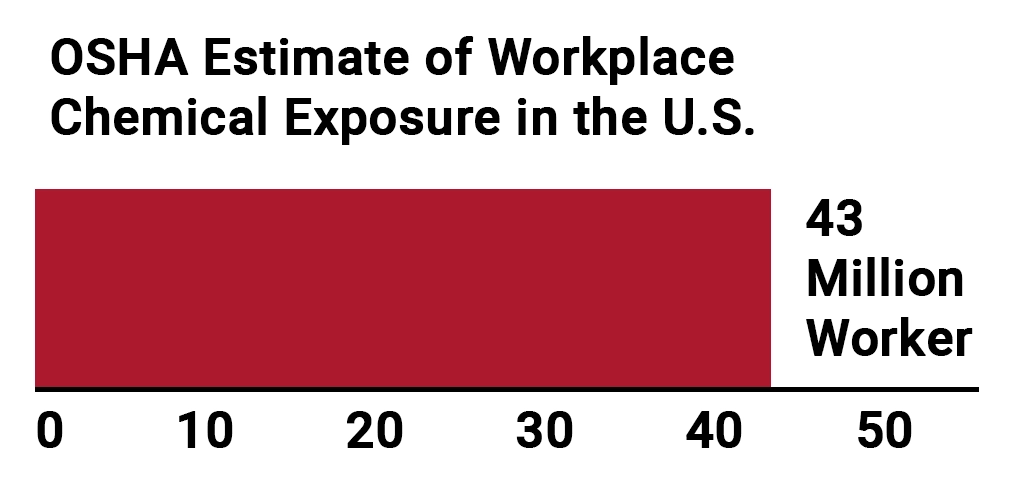

By clearly communicating these risks, a HazCom program protects workers from chemical-related injuries and illnesses, reduces workplace hazards, and helps employers comply with OSHA regulations. According to OSHA, more than 43 million workers in the U.S. are exposed to hazardous chemicals each year, making an effective HazCom program essential for safety and compliance.

What a HazCom Program Really Does

An effective HazCom program acts as your workplace’s chemical safety manual. It tells your team:

- What hazardous chemicals are on-site

- How to safely use and store them

- How to understand labels and safety data sheets

- What to do in case of a spill or exposure

- How to stay compliant with the Hazard Communication Standard

If you’re in manufacturing, auto shops, food processing, construction, or facility maintenance, you’re expected to have a HazCom program in place—no exceptions.

What’s Included in a HazCom Program?

A Written Hazard Communication Plan

This is the foundation. It should describe your approach to:

- Labeling containers

- Maintaining Safety Data Sheets (SDS)

- Providing employee access to information

- Training protocols

And it needs to be accessible—not buried in a filing cabinet.

A Complete Chemical Inventory List

This should include every hazardous substance at your site—no matter how small the quantity. A chemical inventory keeps your SDS library and labels consistent with what’s actually in use.

Standardized Chemical Labeling

Labels must meet GHS (Globally Harmonized System) requirements, including:

- Product identifier

- Signal word (“Danger” or “Warning”)

- Pictograms

- Hazard and precautionary statements

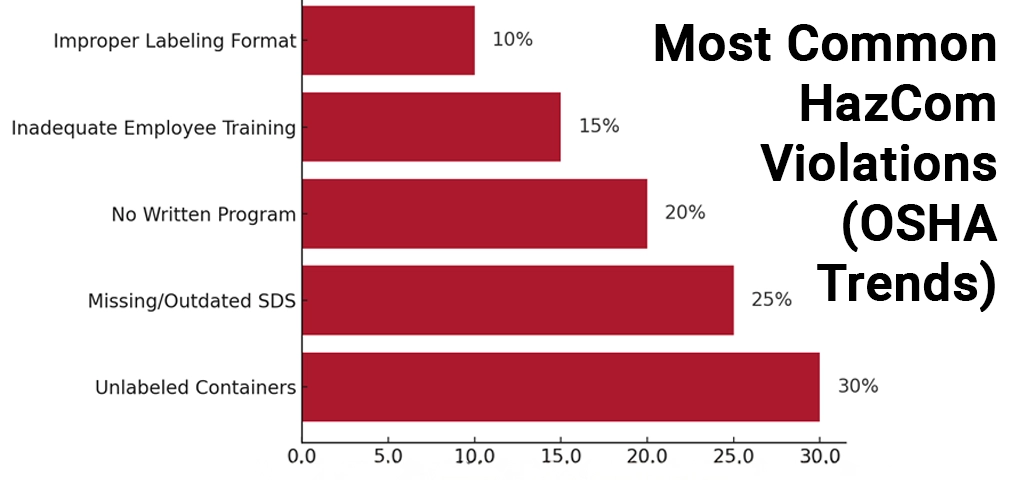

Missed labels are one of the top reasons for OSHA HazCom violations.

GHS Labels and HazCom Compliance

The GHS (Globally Harmonized System) provides the standardized format for chemical labels required under HazCom. Each label must include:

- Product identifier

- Signal word

- Pictograms

- Hazard and precautionary statements

Following the GHS format helps ensure your workplace labeling meets OSHA expectations—and keeps your team informed at a glance.

Accessible Safety Data Sheets (SDS)

For each chemical in your inventory, you must keep its SDS updated and available. SDS provide detailed information on:

- Health risks

- First aid steps

- Storage requirements

- Disposal instructions

They can be stored digitally or physically—as long as access is immediate.

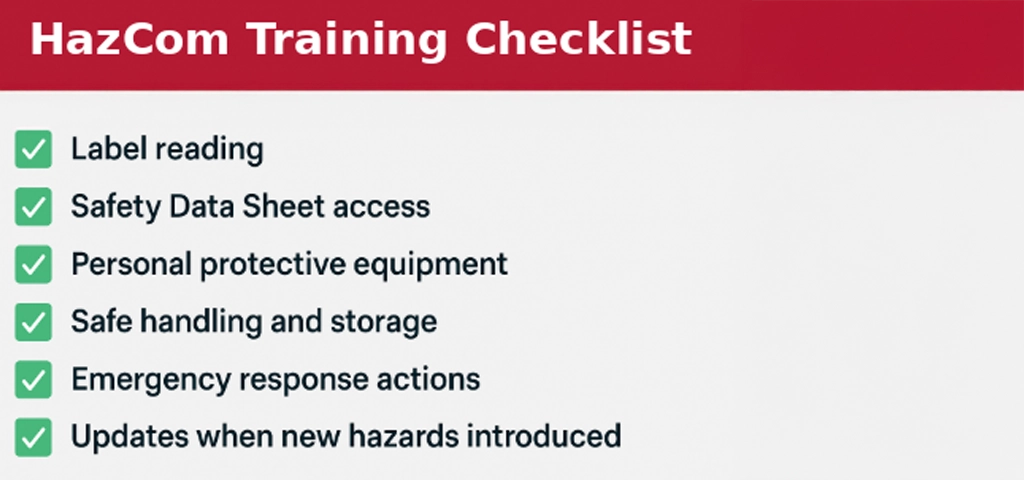

Employee Training on Chemicals

This is non-negotiable. Employees need to know:

- How to read labels and SDS

- Where to find hazard info

- Proper handling, PPE, and response steps

- What to do if they’re exposed or a spill occurs

Training must happen at new hire and whenever a new hazard is introduced.

How One Manufacturer Fixed HazCom Gaps Before OSHA Did

A mid-sized fabrication facility had solvents in secondary containers without any labels. Their SDS binder hadn’t been updated in two years, and new employees weren’t receiving any formal training on chemical handling.

They pulled together a cross-department team and took 4 key steps:

- Completed a chemical audit of all areas

- Updated their written hazard communication plan

- Switched to custom durable GHS labels

- Ran live safety training with department supervisors

The result?

✅ A clean OSHA inspection

✅ Safer workflows across three shifts

✅ Fewer incidents involving spills and incorrect storage

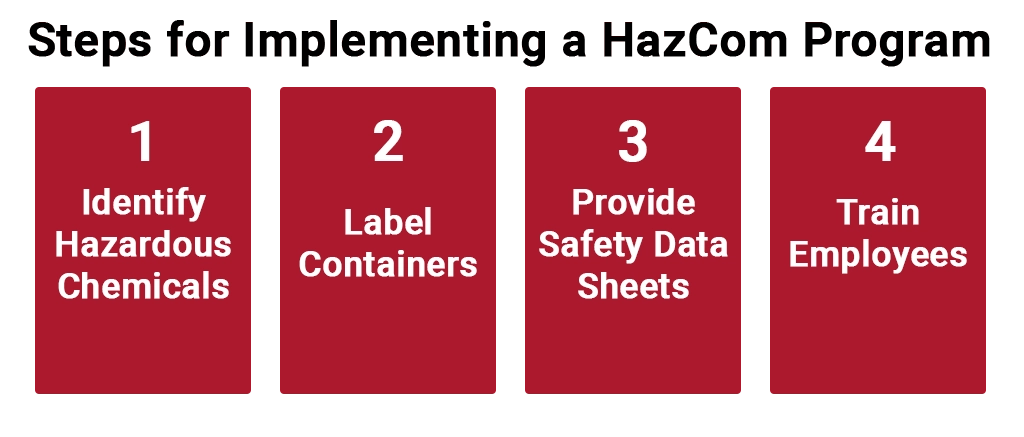

How to Build a HazCom Program for Your Business

If you’re building or improving your HazCom setup, here’s where to start:

1. Identify all hazardous chemicals

Walk your facility and take stock—cleaners, adhesives, fuels, paints, solvents, etc.

2. Gather or request SDS

Ensure every product has a current Safety Data Sheet on file.

3. Label everything

No unmarked bottles, drums, or containers. Use chemical labeling that withstands your environment (heat, water, chemicals).

4. Create a written plan

Describe your program clearly: who oversees it, how SDS are managed, and how training is delivered.

5. Train your team

Make it practical and relevant. Use your own chemicals and labels during the session.

6. Keep it updated

New product? New task? New hire? Your HazCom program should evolve with your workplace.

HazCom Program Requirements for Small Businesses

Small businesses are not exempt from OSHA’s Hazard Communication Standard. Even if you only store a few cleaning chemicals or maintenance supplies, you must still:

- Maintain a chemical inventory

- Provide updated SDS

- Train employees

- Create a written plan

- Label all hazardous containers

Who Needs a HazCom Program?

You do—if your business handles hazardous chemicals. This includes:

- Small businesses

- Contractors

- Labs

- Warehouses

- Service providers

There’s no exemption based on size. Even if you only have a handful of products, you must comply with OSHA’s Hazard Communication Standard (29 CFR 1910.1200).

Avoiding HazCom Penalties

The penalty for noncompliance with HazCom requirements can reach $16,131 per violation, per inspection. Repeated or willful violations can multiply fines and lead to shutdowns.

Common pitfalls include:

- Missing or incomplete SDS

- No written plan

- Faded or missing labels

- Lack of employee training

Make Chemical Labeling Simple, Durable, and Compliant

Labeling is the piece that employees interact with daily. It needs to be legible, durable, and compliant. If you’re printing your own labels or struggling with mismatched supplies, our custom industrial safety labels are built to hold up in tough environments—helping you meet OSHA standards without second-guessing your setup.

HazCom Programs FAQs

To inform employees about the hazardous chemicals they may encounter at work and ensure they know how to handle them safely.

OSHA’s Hazard Communication Standard (HCS) is the regulation that requires employers to inform workers about hazardous chemicals in the workplace. It outlines rules for labeling, SDS access, training, and written documentation—forming the legal foundation of every HazCom program.

Start with a written plan, compile your chemical inventory, gather SDS, set up labeling, and provide regular employee training.

Yes. OSHA requires all employers with hazardous chemicals to comply with the Hazard Communication Standard—regardless of size.

Unlabeled containers, outdated or missing SDS, no written plan, and lack of documented training are among the most cited issues.

Training must occur at hiring and when new hazards are introduced. It must cover labeling, SDS access, handling procedures, and emergency actions.

Absolutely. While HazCom labels must meet strict compliance standards, funny or tongue-in-cheek warning labels can be used in non-regulatory areas to grab attention or boost workplace engagement. If you’re curious about the lighter side of labeling, check out our blog post: 10 Funniest Warning Labels That Will Make You Look Twice. It’s a great reminder that even serious topics can be presented in a memorable and creative way.