Warehouses improve inventory accuracy fast by adding barcode asset tags and scanning tools, giving teams instant updates and cutting manual mistakes.

This simple shift replaces error-prone logs with real-time data, helping operations plan better, avoid delays, and keep stock numbers trustworthy without slowing down the workflow.

How Manual Tracking Fails and Technology Fixes It

Manual logs and spreadsheets often create mismatches, misplaced items, and slow updates. Each handwritten error can throw off orders, leading to overstock or missed shipments.

By switching to barcode systems and real-time scanning, warehouses replace these gaps with accurate, immediate data, reducing mistakes and keeping counts reliable without slowing operations.

Barcode Asset Tags: The Quickest Way to Reliable Inventory

Modern barcode asset tags give every item or shelf a unique, scannable ID. When employees scan instead of writing by hand, updates go straight into inventory software—keeping counts accurate and removing guesswork.

Key benefits include:

- Live inventory data: Always know what’s in stock and where it sits.

- Fewer mistakes: Less human error compared to manual tracking.

- Faster audits: Finish cycle counts in hours, not days.

- Better accountability: See who moved or updated each item.

How to Improve Inventory Accuracy in a Warehouse

- Label Every Item Clearly

Apply barcodes or QR codes on each asset, bin, or pallet with durable inventory labels that stand up to warehouse conditions.

Automate Scanning

Replace paper logs with barcode scanners or apps that update your system immediately. - Use Real-Time Dashboards

Monitor stock as it moves. Dashboards help teams catch errors, check locations, and adjust inventory on the fly. - Train Everyone on the Process

Show employees how to scan properly, handle damaged tags, and report issues so your system stays accurate.

Saving $60K with Better Tracking

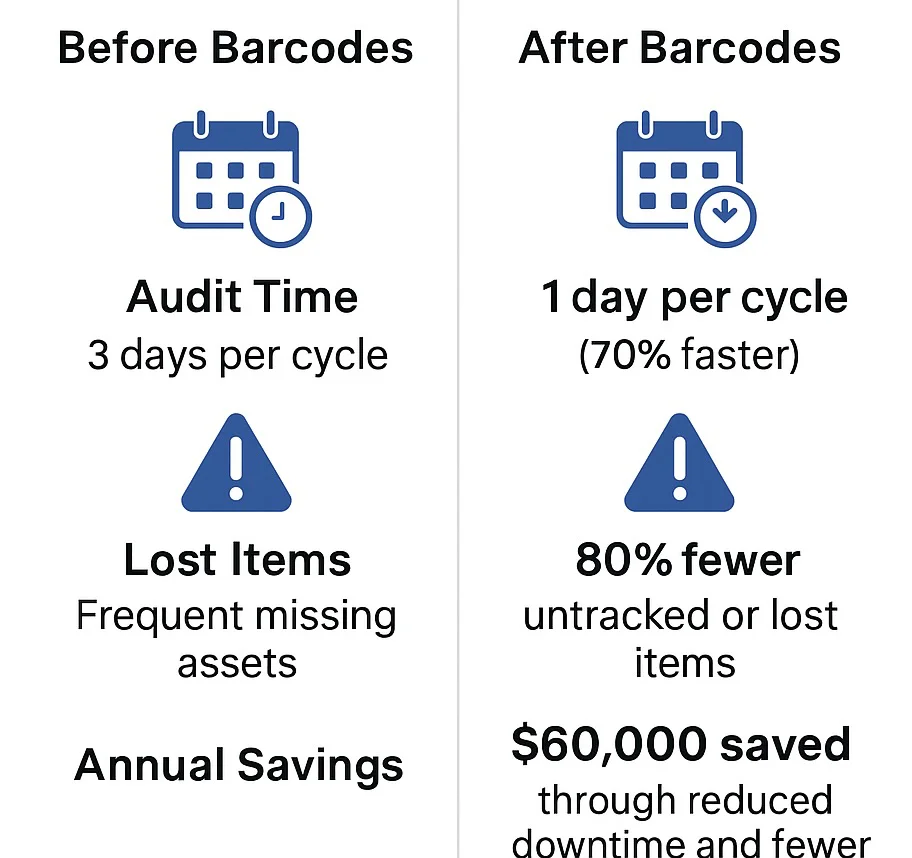

A logistics center upgraded its system by tagging every pallet, dolly, and tool with barcoded labels connected to their inventory software. This simple move turned tracking from a slow, error-prone process into a fast, reliable workflow.

Before barcode tracking:

- Daily counts required hours of manual checking

- Misplaced items often went unnoticed for weeks

- Staff spent time hunting for missing assets instead of fulfilling orders

After adding barcode scanning:

- Audit time cut by 70%—monthly counts that took three days now finish in one

- Lost or untracked items dropped by 80%, slashing replacement costs

- Over $60,000 saved in one year from reduced downtime and fewer asset purchases

By scanning every asset as it moved, the team always knew what was on hand, where it was stored, and who last handled it, eliminating confusion and keeping inventory numbers accurate day to day.

Why Accurate Inventory Data Matters

Whether you run a big warehouse or a small operation, getting inventory right helps you:

- Avoid buying too much or running out

- Ship faster with fewer mistakes

- Keep customers happy with reliable orders

- Reduce losses from missing items

When every asset has a barcode, managers and teams work from the same accurate data, which improves planning and day-to-day tasks.

Ready to Strengthen Your Inventory Counts?

If you’re dealing with missing items or slow cycle counts, better barcode tags could make all the difference. Clear, durable labels help your team keep records accurate and reliable, so you spend less time tracking things down and more time getting work done.

Modern Technology for Inventory Accuracy FAQs

Barcode tags and scanning tools remove manual mistakes, update stock right away, and help teams see exactly what’s in the warehouse.

Use barcode labels on all items and scan them into your inventory system. This keeps counts current without relying on handwritten logs.

Manual counting, missing or unreadable labels, and skipped steps during transfers cause stock numbers to drift from reality.

It cuts mistakes, avoids unneeded purchases, speeds up counts, and makes order picking more accurate.

Yes. Many scanners and apps connect directly to common inventory systems, updating records every time you scan.