What Are Asset Tags?

Asset tags are durable adhesive labels used by organizations and individuals to track and manage equipment effectively. These tags often contain barcodes, serial numbers, and essential company details.

Why Tag Your Equipment?

Asset labels with QR or barcodes make it simple to track items, showing ownership and age details. This practice proves invaluable for inventory management, audit compliance, and accounting accuracy. Moreover, asset tags serve as a deterrent against loss or theft, significantly increasing the chances of recovering lost items.

The 10-80-10 Rule

According to the “10-80-10” rule, the majority of employees (80%) may take company assets if they have the opportunity. A small portion (10%) will never steal, and another small portion (10%) will always steal if given the chance. Implementing asset tagging practices helps mitigate this risk, making it more challenging for individuals to misappropriate company property.

Key Considerations for Asset Tagging

Decide what to tag, such as valuable items, tools, computers, or fixed assets, before purchasing asset tags. Additionally, assessing the need for barcode scanners or reliance on employee smartphones for item check-outs is essential in selecting the appropriate tag type, such as QR codes.

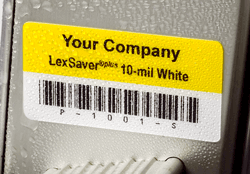

Customizing Asset Tags

Most companies use standard asset tags, but some need special tags to meet their unique needs. Customized “Asset Tracker” tags with smaller barcodes help track accessories or related items separately from the main ID tag.

Tailoring Asset T Practices

Customized solutions may also involve linking tags to specific records for accounting purposes, ensuring comprehensive inventory tracking. Understanding the distinct needs of your organization is paramount when planning your asset tag order.

Protecting Valuable Assets

Expensive equipment is at a higher risk of theft. Standard asset tags are beneficial, especially for the majority of honest employees. However, individuals can remove these tags with time and effort, which provides opportunities for theft.

To counter this, security labels such as VOID and destructible labels are essential. These labels increase the time and effort required for removal, acting as a deterrent against opportunistic theft.

Understanding VOID Pattern

Security silver polyester labels consist of separate text and security layers. When you try to take off the label, the sticky part between the layers breaks. This lets you remove the top layer, but the bottom layer stays. Cleaning off the residue can pose a challenge, as it makes it evident whether someone has tampered with the equipment.

The Destructible Option

Destructible labels are made from a fragile material. Once these labels are firmly in place, they become exceedingly difficult to remove. Any attempt to peel them off results in fragmentation, with the small fragments adhering tightly to the surface. This leaves evidence of tampering, often deterring potential thieves after the first or second break.

Assets in Challenging Environments

For assets stored outdoors or in harsh environments, specific types of asset tags are necessary. We recommend using anodized aluminum foil, anodized metal, destructible, or LexSaver®plus materials for outdoor use.

LexSaver®plus is a tough and durable material. It can withstand high temperatures, tearing, abrasion, chemicals, and physical strain. This makes it perfect for challenging situations.

Durable Options

Anodized aluminum foil asset tags are highly durable, with embedded barcodes and serial numbers visible even after extended outdoor exposure. Metal and foil tags stick well, can handle sun, salt, solvents, and last 20 years outside.

Application Best Practices for Asset Tags

- Commence with a clean, dry surface. Clean the surface with alcohol or a lens wipe to remove dirt and oil. Make sure it’s dry before putting on the label.

- Clean and dry your hands before taking off the label from its liner when applying asset tags manually.

- Carefully lift one corner of the label, then remove the rest from the liner without touching the adhesive.

- Put asset tags on the back or side of movable things, not underneath, for easier access. The exact alignment is not necessary. Standardizing placement can facilitate inventory management.

- Place the label gently on the surface and smooth it out, starting from the first edge that you put down.

- Allow the item to remain at room temperature for at least 24-48 hours after application. Destructible and security labels should cure for 48-72 hours, if possible.

Using these best practices ensures asset tagging is effective and helps secure and manage valuable assets. Ready to purchase custom asset tags?