Plant assets are long-term, physical assets used in business operations to produce goods or services. These include equipment, buildings, machinery, vehicles, and land—assets that can’t easily be moved and aren’t intended for resale. They’re the backbone of production and logistics, and managing them well protects both uptime and investment.

When labeled and tracked properly with custom asset tags, plant assets become easier to manage, maintain, and account for. That means fewer breakdowns, more accurate audits, and a longer useful life for your most valuable tools.

Examples of Plant Assets

Plant assets aren’t just machines and heavy equipment—they’re every physical item that keeps your facility ticking. And guess what? Asset Tags and Equipment Labels are their secret sidekicks.

Let’s walk through real examples of plant assets and how clever labeling helps track, protect, and manage them.

What Is Plant Asset Management?

Plant asset management is the practice of tracking, maintaining, and optimizing the physical assets that keep your operations running. It includes everything from machine maintenance schedules to accurate depreciation tracking.

The goal: extend the life of critical assets, reduce unexpected downtime, and support smart capital planning.

Why It Matters

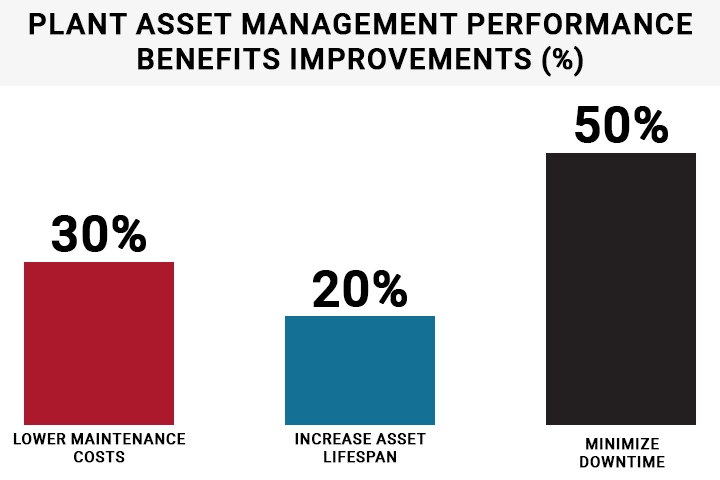

According to market research, effective plant asset management can:

- Reduce maintenance costs by 15–30%

- Extend asset lifespan by 20% or more

- Cut downtime by up to 50% in equipment-heavy operations

(Source: MarkWide Research)

Without good asset visibility, even well-run facilities end up wasting time chasing tools, missing maintenance windows, or over-ordering parts.

Real-World Example: RFID in Construction

The Byrne Group, a UK-based construction firm, implemented an RFID-based plant asset tracking system to manage tools and heavy equipment across multiple sites. Result?

- Faster equipment check-ins

- Reduced loss and theft

- Streamlined internal audits

This same logic applies whether you’re tagging a generator, a robotic arm, or a commercial HVAC unit. The principle is simple: If it’s critical to operations and expensive to replace, track it.

How Asset Tags Improve Plant Asset Management

Asset tags link physical items to digital records, making plant asset management more precise and reliable. Whether you use barcode, QR, or RFID tags, the label becomes the access point for maintenance records, location tracking, and asset performance history.

Core Benefits:

- Quick identification with handheld or mobile scanners

- Faster audits and inspections with accurate data on file

- Lifecycle tracking from purchase to retirement

- Lower total cost of ownership through better maintenance

Even better, most systems let you set alerts when assets are due for inspection, cleaning, or recalibration—reducing preventable failures.

Choosing the Right Labels for Plant Assets

Not all tags are up to the job. Harsh environments, dirty hands, and outdoor exposure demand more than a generic paper label.

What to Consider:

Material Options

| Material | Best For |

|---|---|

| Polyester | Chemical resistance, high durability |

| Anodized Aluminum | Extreme environments, permanent ID |

| Vinyl | Curved or uneven surfaces |

Adhesive Strength

- Permanent: Ideal for equipment with long service lives

- Tamper-Evident: Useful for safety-critical systems or compliance audits

Finish & Print Type

- Laminated: Protects against abrasion and cleaning solvents

- Thermal Transfer: Sharp, durable barcodes and text

Matching your label to the asset’s use case ensures better performance and fewer replacements.

When Should a Business Start Tagging?

The best time to start is before things get out of hand. If you’re scaling operations, onboarding new equipment, or experiencing inconsistencies in audits—those are strong signals.

Use tagging to:

- Inventory older equipment still in use

- Track newly purchased assets from day one

- Transition from spreadsheets to software-driven systems

- Prepare for audits or insurance reviews

Every unlabeled tool or untracked forklift is a potential blind spot.

Before You Choose a Tagging System

If you’re not sure where to start—or you’re ready to bring more order to your operations—choosing the right plant asset tags can make the process easier. We’ve helped thousands of teams label with confidence by matching materials and adhesives to the environments they work in.

Plant Assets & Tagging FAQs

Plant assets are long-term, physical assets used in operations—like machinery, tools, buildings, and vehicles. They support business functions and depreciate over time.

It’s the structured process of maintaining and optimizing plant assets to reduce downtime, extend asset life, and support accurate financial reporting.

Tags provide a unique ID for each asset, linking it to a digital record for tracking location, maintenance history, and lifecycle data.

Polyester and anodized aluminum are ideal for harsh environments. Laminated options resist chemicals, water, and abrasion.

Yes. With digital records tied to each tag, audits become faster and more accurate. Tags also support OSHA and internal tracking requirements. For example, in programs like HazCom, proper labeling and asset identification are essential for regulatory compliance and workplace safety.

Absolutely. Conduct a walkthrough, label all active assets, and import details into your tracking system for full visibility.

Most asset management platforms support barcode, QR, or RFID scanning. The tag simply serves as a bridge between physical and digital.