Clear breaker panel label templates help electricians and facilities teams identify circuits fast, keep inspections smooth, and cut downtime during repairs. Using durable graphic overlays, you can replace faded notes or tape with professional, long-lasting labels.

Quick Overview

- Use templates to speed up troubleshooting and maintenance

- Apply graphic overlays for durability in tough environments

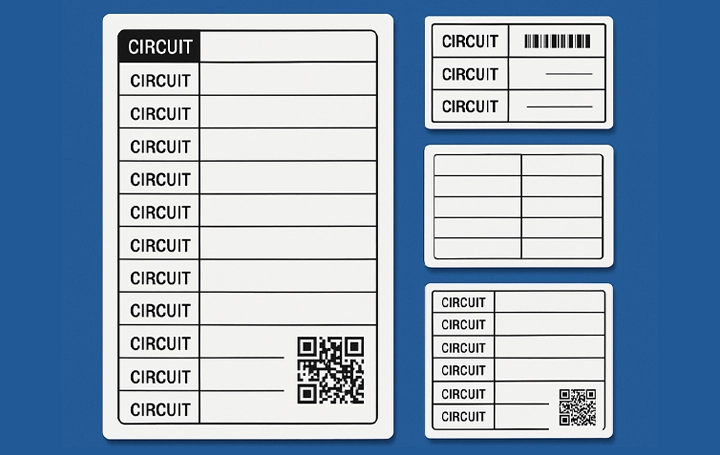

- Customize labels with circuit details, barcodes, or QR codes

- Meet OSHA and NFPA electrical labeling requirements

The Role of Breaker Panel Labels

A breaker panel is the central control point of any electrical system. Without proper labeling, small issues can cause long delays. Templates provide:

- Fast circuit identification during troubleshooting

- Consistent labeling across multiple sites

- Professional appearance for compliance inspections

- A safer working environment for staff and contractors

Breaker panel labeling is just one part of keeping facilities organized. Many teams also use barcode systems for assets and inventory, see our post on how to implement a barcode system in a warehouse for more ways to streamline operations.

According to OSHA 1910.303, electrical equipment must be clearly marked to indicate circuits and hazards. The National Fire Protection Association (NFPA) also reinforces this requirement through its NFPA 70 National Electrical Code, which outlines electrical labeling and safety standards.

Poor or missing labeling is a common source of OSHA electrical citations, with serious violations carrying fines that can exceed $14,000 per incident.

In one manufacturing facility, unclear panel labels led to the wrong circuit being shut down, halting production for half a day. Situations like this highlight both the compliance risk and the operational cost of poor labeling. Using templates is a straightforward way to avoid that risk and meet safety requirements.

Graphic Overlays for Breaker Panels

Graphic overlays provide durable, customized labeling for breaker panels. These overlays are typically made from polyester or polycarbonate films with industrial adhesives, giving them resistance to moisture, cleaning chemicals, and heavy use.

They can be customized with printed legends, color coding, or even barcodes to fit the facility’s needs. Their advantages include:

- Long-term resistance to abrasion, heat, and moisture

- Space for typed fields, barcodes, or QR codes

- Consistent design across facilities

- Clean updates without crossed-out notes

Graphic overlays can also be made to fit specific panel layouts, providing a consistent look across facilities and lasting performance in demanding environments.

How to Use a Breaker Panel Label Template

- Download a template sized to your panel

- Fill in circuit details digitally before printing

- Print on durable label stock or order overlays

- Clean the panel surface thoroughly before applying

- Apply the overlay smoothly to avoid air pockets

Tip: Keep a digital copy of your filled template so updates are quick and consistent.

Where Templates Make the Biggest Impact

- Industrial sites with critical machinery resets

- Hospitals and labs where downtime is unacceptable

- Schools and offices with frequent maintenance calls

- Residential complexes managed by rotating staff

Industry studies show that unlabeled panels can add 30–60 minutes of extra troubleshooting per incident, which quickly adds up to lost labor hours and extended downtime. Think about your last service call, were the panels you worked on easy to read, or did you have to trace circuits by hand?

Common Labeling Mistakes

It helps to picture the difference: a poorly labeled panel often has faded handwriting, mismatched notes, or tape curling off the surface. A well-labeled panel uses a clean overlay with legible text that matches the breaker layout. The contrast is immediate in terms of safety and usability.

- Handwritten notes that fade or smudge over time

- Labels that don’t match the actual panel layout

- Updates made in pencil or marker instead of a printed template

- Failing to update labels after new circuits are installed

- Using tape or paper that peels or becomes unreadable

When to Update Breaker Panel Labels

- After adding or removing circuits

- When equipment is replaced or relocated

- During scheduled safety or compliance inspections

- Any time handwriting becomes unclear or faded

Breaker Panel Label Templates FAQs

A breaker panel label template is a pre-formatted sheet designed to record circuit numbers and descriptions. It provides consistent, easy-to-read labeling compared to handwriting.

Graphic overlays are printed on tough materials with strong adhesive backing. They adhere directly to the panel surface, offering long-term readability in demanding environments.

Yes. OSHA and NFPA both require clear electrical labeling. Templates and overlays provide consistent labeling that simplifies inspections.

Keep your template file saved. Update fields when circuits change, reprint, and replace the overlay. This avoids crossed-out notes and keeps labeling professional.

Here at MaverickLabel.com, free printable breaker panel label templates are available. You can also find durable graphic overlays for panels that need long-term clarity.

Breaker panel labels should be reviewed at least once a year during scheduled maintenance or safety inspections. They should also be checked any time electrical work is performed to confirm circuits are still accurate and readable.