Labels are important for sharing information and creating a brand identity, not just pieces of sticky paper. At Maverick Label, we value precision and detail. That’s why we’re exploring the complex layers of our labels. All our labels with adhesives are pressure-sensitive labels, and these types of labels have the same basic layers in common.

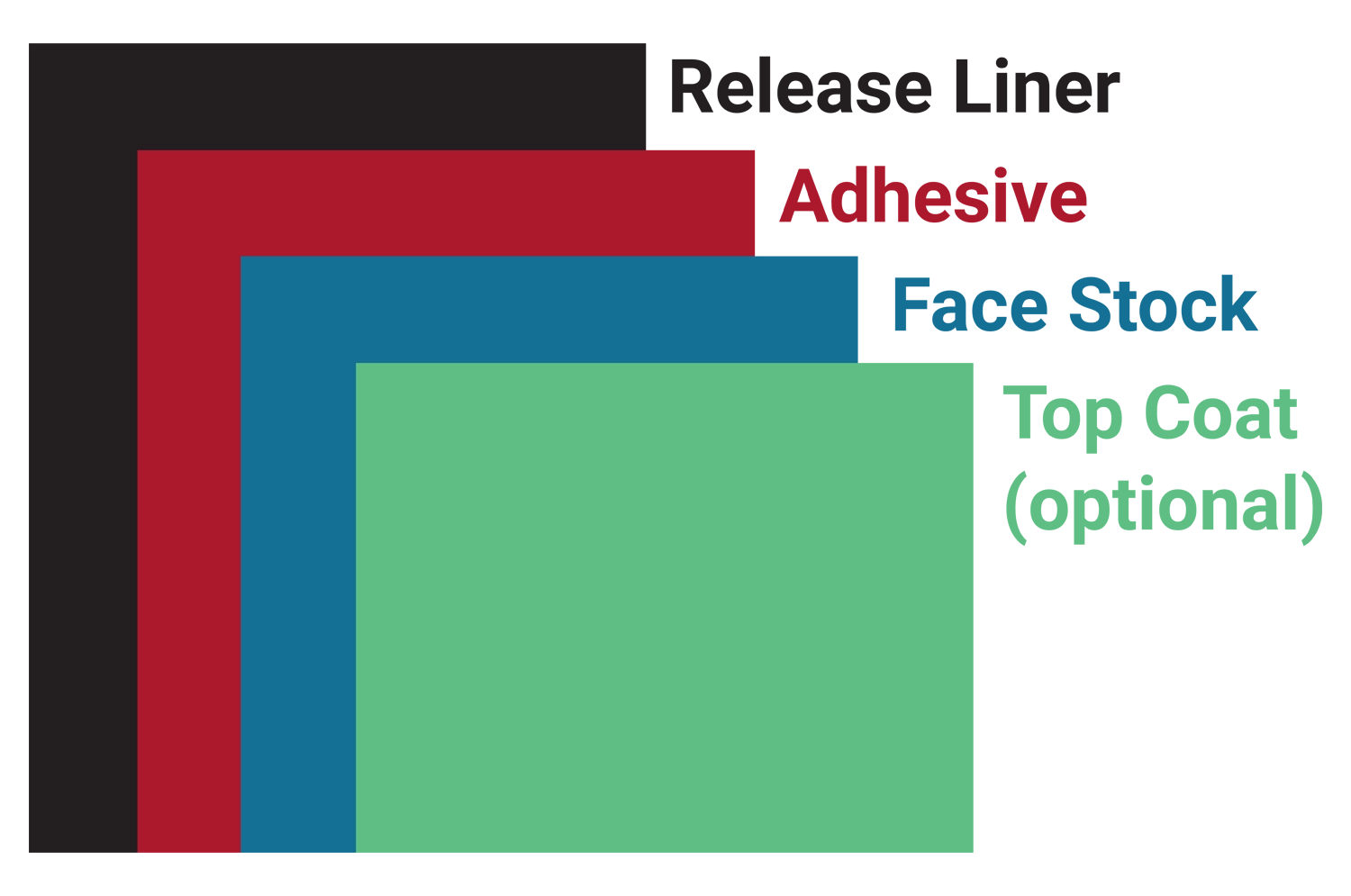

The main label layers for pressure-sensitive labels are the face stock, the adhesive, and the release liner. You also have the additional “finish” option of a top coat. And, of course, your artwork and product information fits in there, too!

(Our non-adhesive labels include things like parking hang tags, magnetic labels, and tie-tags. They don’t include adhesive or the release liner, and material choice is generally limited.)

Face Stock

Face stock is the label material. It can range from paper to metal, with all sorts of polyester, polypropylene, and vinyl materials as well. What material you want will depend on what you plan to use your labels for.

The face stock holds the ink colors, text, and artwork you send us. Generally, we print this on the upper surface of the face stock. The color of the face stock can play a part in your artwork. We have a wide array of colored materials, as well as holographic and foil films and inks.

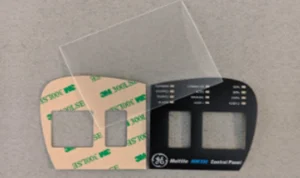

We print on the bottom of Lexan® and then add adhesive with release liner afterwards.

On these labels, any artwork or text is sandwiched between the material and the adhesive. This adds a large amount of protection to the printed label, and also allows for “adhesive free” areas in the label.

People usually want this process for industrial and heavy equipment applications; most other labels don’t need this sort of protection or adhesive-free areas. If you want a bit more protection for your product labels, a regular varnish or laminate is usually sufficient for most applications.

Adhesive

Most of the materials we use to make your labels come with the adhesive already applied. This means you need to consider how you will use the label before deciding on a face stock material. Some applications and surfaces require a stronger adhesive than others.

We have a number of different adhesive types, ranging from super strong (elephant grip, for example) to none at all (static cling or magnetic labels). Some of our labels are removable, while others are great for hard-to-stick places like curved surfaces or slick LSE plastics. The aggressive adhesives are available on our “short run” equipment line (where your minimum order is one label).

Regardless of strength, all our adhesives are clear and do not affect the color of either the label face stock or the substrate where you put the label.

Release Liner

The liner is different depending on the stock and adhesive, but usually has silicone coating. This smooth surface makes it easy to remove labels from sheets, rolls, or pieces without them sticking together. It is mostly commonly white or blue, but can be other colors.

Top Coat – Optional Label Layer

As a last label layer, you can opt to add a laminate or vanish as a top coat. This adds a bit of water or oil resistant to the face stock, or a bit of shine.

We offer top coats that range from spot varnish – applied to only certain areas of the label, it adds sheen and subtle highlights – to full coats of laminate or varnish.

Another, fairly radical “top coat” possibility is a domed label. These labels are pretty cool. A clear, thick layer of polyurethane is added over the completed label. This dome is weather and UV resistant, and the polyurethane adds luster to the label as well.

Domed labels do take a little longer to ship to you, as the dome has to cure or harden before the labels can be packed up and sent out. These labels are best for very flat surfaces, as they are no longer very flexible once the dome hardens.

If you want to know more about any of our label materials, laminates, or adhesives, or have questions about which combination is right for your application, our customer care reps can help you out.